Engaging consumers in immersive and innovative ways that is environmentally friendly

Pranil Chandra August 4, 2022

Speak to a Print Expert

Creating visual touchpoints that challenge the senses is more important than ever. We now live in a digital age where most purchasing interactions happen online – and soon, the metaverse. Unfortunately, this comes at the expense of human connectivity.

That’s why visual activation and pop-up displays or booths in retail, shopping centres, shows, events and exhibitions are more important than ever. They offer an opportunity to fulfil the experiential craving we have rooted in us to connect with things that are tangible and physical. Connecting with a brand and the wonderful people they employ takes us on a sensory journey that is not possible online.

The issue that’s been rising over the years is that the materials used by brands that ARE engaging with their consumers in immersive and innovative ways are largely not environmentally friendly, ultimately having a negative impact on the planet. Yet, “What can we do to reduce our carbon footprint” has become something of a buzz phrase.

Here at NEXT, it got us thinking: do customers really care about the environmental impact products have? Can these events continue in an environmentally conscious way by utilising sustainable printing practices? Is it possible to provide sustainable printing solutions at an affordable price, and still pull off a spectacular event?

We found that the answer to all of these is YES.

From the initial design conception and development, to eco-friendly printing, to packing and shipping, and all the way to disposal, NEXT has come up with processes to achieve eco-friendly display stands and green event ideas.

At NEXT, we have decided to stray from conventional printing to a greener approach, which includes UV printing.

UV printing:

Conventional printing uses solvent-based inks which evaporate into the environment and release toxic volatile organic compounds (VOC).

UV printing dries inks immediately after printing using UV light to harden the substrates

This decreases toxic evaporation into the environment and prevents ink smudging, allowing your prints to stand out for longer!

Drying using conventional printing and solvent-based inks not only takes days following the printing process due to the makeup of the paper and the properties of the ink, but also proves harmful to the environment due to the non-recyclable nature of traditional MDF and toxic properties of solvent-based inks.

Spray powders are often needed to aid in the conventional drying process, and these chemicals, when absorbed into the paper, can dull or dilute the colour of the ink. When using UV printing, drying is immediate and non-toxic, making it a highly regarded green technology as well as a brighter, sharper image for your next printing project!

At NEXT, UV printing is done on cutting-edge printers, ensuring that your prints start off at the highest quality. This technology leaves almost no carbon footprint as it removes water usage from the printing process!

Tiling is done with advanced software, maximising print yield and minimising waste material

When seeking the ideal sustainable printing practice, there are various alternatives for companies to use, including bamboo, reclaimed wood, plastic from recycled water bottles and inks and substrates with fewer toxins such as soy and water-based inks.

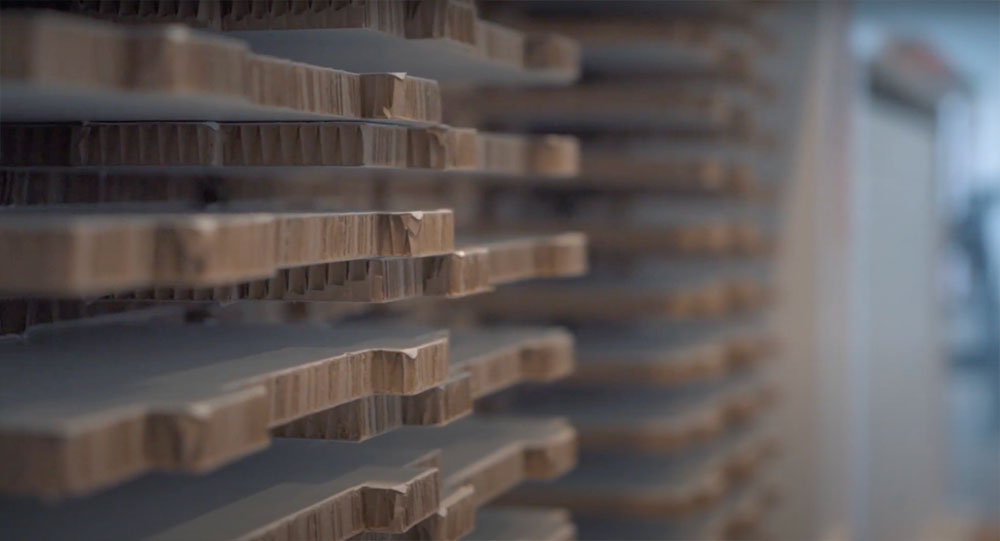

Here at NEXT, Re-board, sourced from FSC certified sustainable sources, is a green-friendly alternative to the traditional MDFs (medium-density fiberboard), which often utilises non-biodegradable adhesives, such as formaldehyde.

In addition to the current sustainable practices in place at NEXT, we are expecting to implement a new initiative in the next three months, where used materials from clients can be collected and recycled.

Another highly praised green printing solution to complement Re-board is DISPA, with their paper board being made of 100% cellulose fiber, meaning it is also 100% recyclable. The uniquely embossed formed paper gives it strength and rigidity, and allows high quality print results for both UV and screen printing.

Why Re-board?

Made of 100% recyclable paper and non-toxic water-based adhesives

Lightweight paperboard, meaning easy construction and removal

Versatile, allowing you to create any shape or design you wish

Possesses a large amount of holding strength due to its unique fluted centre – you can even put a car on it!

If you’re trying to go green we’d say it’s our #1 choice – that is unless you’re having someone try walking in heels on it…

Although product material is a huge factor in creating an environmentally conscious event, it is not the only aspect to consider. Material transportation plays a huge part in our carbon footprint.

At NEXT, one of the things that’s at our core is being part of the solution that creates a better future for us all. This is why, especially in the case of large-scale events, eco-friendly solutions are part of our core offering, utilising Re-board and other biodegradable materials.

When creating a green-friendly event, we try to avoid using plastic based materials for packaging and transportation where possible. At NEXT, we use Re-board paperboard that has been fully recycled and repurposed to package your event design. This way, the Re-board product has a full circle of life and creates a recyclable alternative to other, more environmentally harmful, packing materials.

Heavier materials, such as the commonly used MDF, require more manpower, increasing the carbon footprint drastically even in simply getting the materials to an event.

Reboard’s light weight nature reduces transport volume and shipping costs, thus reducing truck and air fuel in the process.

Not only does Reboard displays have a shorter execution timeline comparatively, it’s total cost of ownership is drastically reduced when taking into consideration the assembly process…

All in all you can say it’s quicker to install and requires fewer people. But what does this mean? Well, it really comes down to the commonly used phrase “Time is money”. If we break it down compared to a less environmentally friendly material such as MDF, for example, installation costs and time decrease with the amount of people and labour hours required on site. To add to this the duration and cost of rent prior to event commencement are much lower.

One of the best ways to make your event as green as possible and with zero waste is to reuse!

Re-board is designed to be strong and keep its shape, meaning that you can repurpose your existing designs for other events.

When your Re-board installation does complete its lifecycle, it can be picked up by our waste management team and taken to the recycling facility.

On arrival, the Reboard is bailed and prepared to be fully recycled into paper and packaging material. This process creates a closed loop, giving the material a new life. The water-based adhesives used in the paper board allow it to be fully recycled as paper and be 100% biodegradable, ensuring the circle of life is complete for your product.

There really is no other product that can tick all the boxes like Reboard, and if you’re looking for a trusted advisor that can help you take the steps towards a greener event on a budget, feel free to get in contact with our friendly team!

*

Here at Next Printing you can pick and choose from a range of services tailored to your needs:

Project management

Industrial Design & Graphic Design

Colour management

State of the art printers

Fabric printing

Digital cutters

Fabric finishing

Custom installation

Pick and Pack

Set up & Packdown

Waste Management

Recycling partnerships

Reach out to your account manager or contact us below.

We'd love to send you innovative tips, news and offers from the world of print and marketing.

Client experience officers are available to answer any questions you have. Use the form below to quickly let us know what you need!